- Home

- Capabilities

Our Capabilities

ODIN maintains steady production, handling vibrant designs and product developments through advanced machinery. Along with having our mature supply chain, we also save up on materials to ensure we have enough to mass produce zippers. Our factory has over 165 people, with years of experience designing and helping construct zippers with precision.

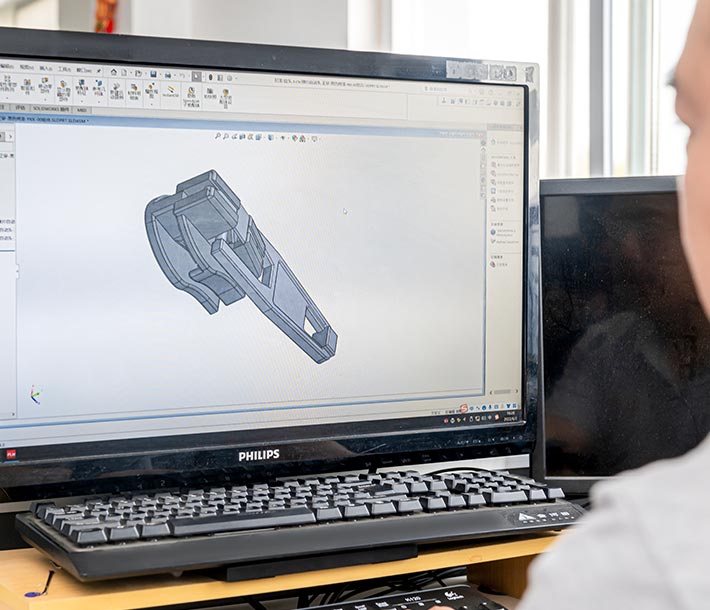

Stucture Design & Engineering

With 44 patented technologies, including waterproofing, we are capable of realizing different functions and designs for your zippers. Having over 20 kinds of independent research and development equipment allows constantly updated product catalogs to satisfy diverse market preferences and keep up with trends.

Sustainable Products Process

Chemically Recycled Zipper

As we acquire recyclable materials, we develop chemical and material recycling technology to lower energy usage, C02 emissions and the application of crude oil, preserving the environment. We used post-consumer polyester, which is perpetually recyclable to reduce the need for using more materials and thus save on costs for zipper mass production.

Mechanically Recycled Zipper

To mechanically increase the amount of recycled content on your products, we use PET bottles and other recyclable plastics and materials to construct our zippers. With advanced mechanical recycling technologies, we can minimize waste production and maintain a steady stock of resources for mass production.

Standard In-house Manufacturing Process

Within a steady production process, we produce coils, fix chain teeth, weave tape, handle thorough ironing, cut according to your requirements and attach the slider. We coordinate with different production lines and workshops to ensure stable mass production of zippers, as well as constant tests in every step.

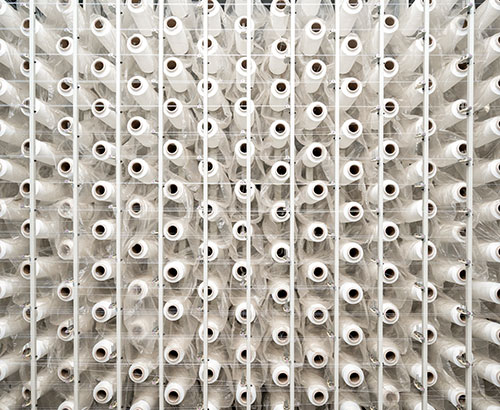

Coil Production

With four strands of wire forming the center line, our fully automatic yarn hanging machine surpasses the performance of our peers that use 2 or 3 strands to make stronger coils.

Using advanced yarn hanging machines ensures efficient production as our machines can constantly run for 4 months to meet demands.

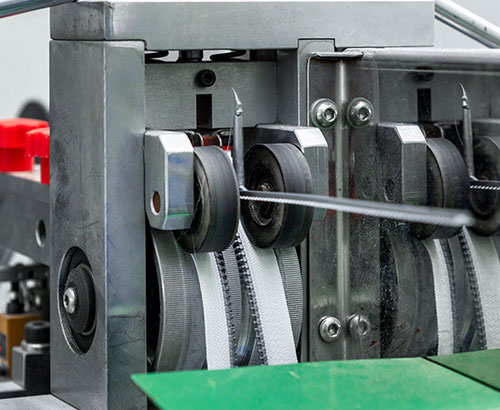

Quality Tapes

Using flexible fabric material, we create specialized zipper tapes that guarantee smoother sliding up and down along the chain of the zipper. As we sew the tape and fasteners together, we test the tape for any wrinkling or quality issues to ensure they are fit to the zipper type and maintain their shape.

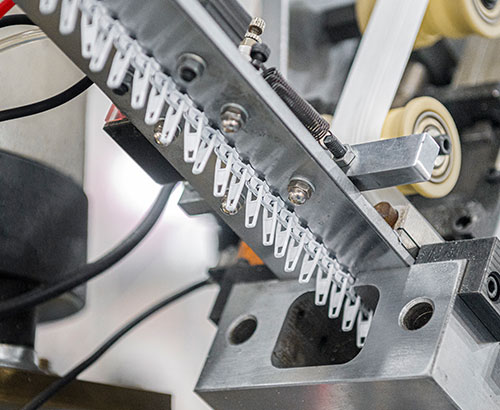

Fix Chain Teeth

After making the coil teeth, we use thread to fasten the pieces together to give every part stability when the zipper is used.

There are also molded teeth made with resin within our injection mold machinery, offering a more accurate shape. Whether metal or plastic, we put the zipper teeth together for a tighter connection.

Degreasing, Ironing, Dyeing

Coming in vibrant colors and finishes, our zippers display your eye for quality and attention to detail as they can match any application you require. We use the degreasing ironing machine to degrease, dye, and iron the zippers so that they maintain their polished, smooth feel when used by your customers.

Attach the Slider

We make the upper and lower ends of the zipper meet by sticking the parts together with clean glue that prevents the zipper from jamming. Carefully, we attach the slider and test if it can easily open and close, ensuring the zipper’s performance before delivery.

Cut on Demand

Our precision in making zippers helps us produce the zipper sizes you require and make as many as needed within a limited time to meet high demand.

Our sizing machines position the zipper according to your required length and then cut them to make the zippers exactly sized.

Critical Quality Indicators Testing

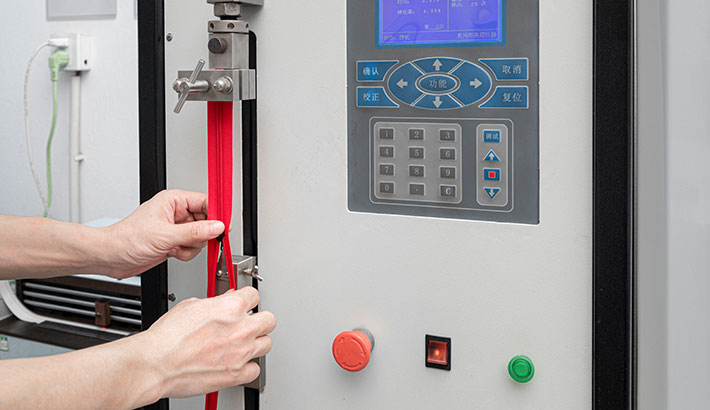

Tensile Testing

We use our tensile testing machinery on our semi-finished and finished zippers to determine how durable our zippers are based on the different fixtures that you require.

Zipper Reciprocating Testing

We use specialized fatigue testers to measure the performance of our zippers through reciprocating opening and closing of the sample under vertical and lateral tension at 30 times per minute.

Salt Spray Test

To see how well our zippers withstand corrosion, we place metal zippers and electroplated sliders under a concentration of sodium chloride and ensure the zippers meet your performance requirements.

Wash-resistant Color Fastness Test

By putting our zippers under washing fastness, we test the textile color to guarantee the quality of the zippers while also checking for impurities and preventing health hazards.

Standards Washer and Dryer

Using ISO standards washer and dryer to check for paint peelings, wear and tear determines the degree of shrinkage on the elongation of our zippers.

Torque Test

Within the torque test, we see how our zippers react when turned by ensuring they do not break when each side of the chain the slider lock is on gets pulled in opposite directions.

Color Consistancy Test

We use color matching machinery to ensure that every zipper we produce matches your specifications and appears alike, maintaining our consistency before we deliver to your premises.

Abrasion Resistance Test

To test the strength of our zippers, we apply much pressure on the surface to see how much our zippers withstand abrasion and scratching, ensuring they can be used for long periods.